News

Employee story: starting a career in a small company

At the beginning of January, I completed my seventh year at EPSE, and I can somewhat reflect on my journey

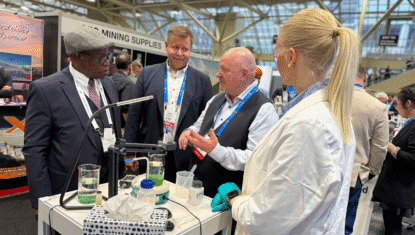

EPSE’s 2025 wrapped

When EPSE’s team is asked what stands out most from 2025, the answers consistently point to the Green Zone concept,

Scale up solutions expert joins EPSE team

EPSE has gained a new employee, Severi Lintula, who is responsible for technical planning during the scale-up phase and for

EPSE and Samruk-Kazyna Ondeu sign a MoU to implement the Green Zone program

EPSE and its US affiliate EPSE Technology Inc. have signed an Memorandum of Understanding (MoU) with the Kazakh state-owned Samruk-Kazyna

Stay up to date with our latest news and developments!

Innovative EPSE™ Method works on up to 50 metals in one treatment

The EPSE™ Method is tested for 50 metals including nickel, arsenic, copper, uranium, chromium, zinc and many more. The treatment produces a metal-free overflow and an practically insoluble multi-metal precipitate. The cutting edge water treatment technology is not dependant on temperatures lowering your company’s energy costs.

Read more of the operating principle and the advantages of the EPSE™ Method here.

Tackling metal contamination in industry

Industrial processes often release heavy metals into wastewater, posing serious risks to human health and the environment. These contaminants are toxic, persistent, and difficult to efficiently remove with conventional methods. Reliable water treatment is essential to meet regulatory standards and enable safe water reuse.

Critical aspects to which we are committed

- Compliance with environmental regulations – water must meet all applicable local, national, and international environmental standards and permit conditions

- Protection of receiving ecosystems – the effluent must not harm aquatic life or disrupt ecological balance

- Continuous monitoring and transparency – discharge must be continuously monitored to ensure compliance, accountability, and early detection of deviations